Sort Inspections (SI)

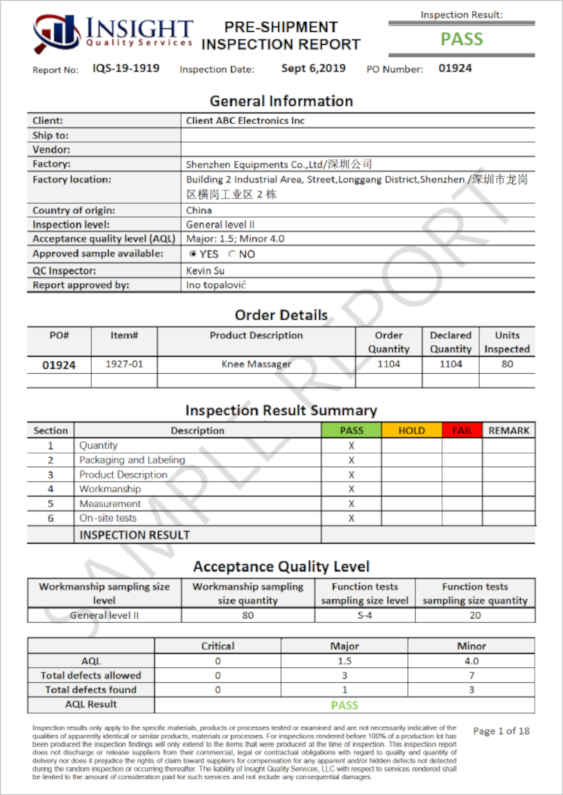

Download a Sample ReportWhat is a Sort Inspection?

A Sort Inspection (SI) is necessary when defective units need to be separated out from your shipment due to one or more known issues. This inspection can be conducted at your factory, a distribution center, or another location. Some examples of relevant issues are:

- Unwanted color variations

- Cracks, chips, or scratches

- Missing parts or components

- Problems with coating

- Mold or other damage

Inspectors go through 100% of your products to separate the good units from the bad. Then, you receive a report on the results from the sort. Our inspectors are highly trained and work diligently to ensure all defective units are removed. That way, you can feel confident that they will not be sold.

Why Should You Conduct a Sort Inspection?

Sort Inspections are important when there is a specific problem with certain batches that were part of your shipment. They allow you to:

- Separate out all defective units

- Get an exact count of defective and acceptable units

- Move forward with only the acceptable units

These inspections enable you to get the maximum number of non-defective units shipped, distributed, and into stores. They help you reduce the number of returns and improve customer relations.

Download One of Our Sample Inspection Reports

Global Coverage, People-First Approach

- China

- India

- Vietnam

- Bangladesh

- Pakistan

…and more

Need Coverage in Your Region?

Why Choose Insight Quality?