Product Inspection Services

Download a Sample ReportWhat is a Product Inspection?

Product Inspections are an important part of an effective quality control program. They allow you to get a snapshot of the quality of your shipments and take corrective action before they make the journey overseas.

In a product inspection, a neutral third-party inspector travels to your supplier’s facilities. They follow industry-standard practices to determine whether your products:

- Meet safety standards,

- Are in compliance with regulations, and

- Meet predefined standards for quality.

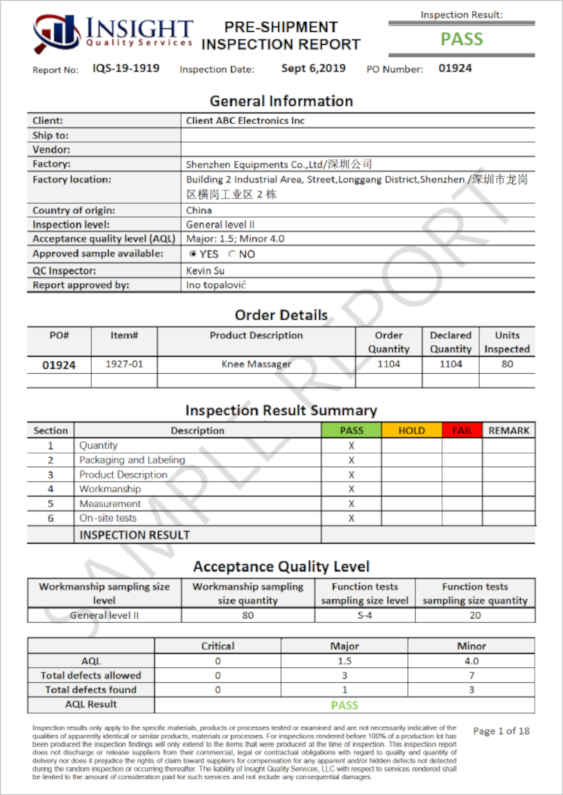

At the end of the inspection, you receive an inspection report. The report provides detailed information about the inspector’s findings, along with photographs. If there are any issues, recommendations are provided to help you manage them in the most effective way possible.

Why Should You Conduct Product Inspections?

Your suppliers have their own quality control processes in place. However, a neutral third-party can maintain a more objective view and represent you effectively at the factory. Product Inspections allow you to:

- Ensure product quality and safety

- Avoid late shipments and costly recalls

- Monitor the manufacturing process

- Reduce customer issues and complaints

At Insight Quality, we work to help ensure that the shipment you receive meets safety requirements, is compliant with regulations, and meets your standards for quality.

5 Types of Product Inspections to Consider

We provide a wide range of quality control services to importers. Our inspection services cover the various stages of the production process. We conduct the following inspections

The most common type of inspection — also called a Final Random Inspection (FRI). Conducted once your products are 100% complete and at least 80% packaged.

Conducted once at least 20% of production is completed.

Conducted once raw materials are received at the factory and they are ready to begin production.

Conducted when an issue is discovered and defective products need to be separated from acceptable ones.

Conducted once products are 100% complete, 100% packaged and are ready to be loaded into a container.

Download One of Our Sample Inspection Reports

Global Coverage, People-First Approach

- China

- India

- Vietnam

- Bangladesh

- Pakistan

…and more

Need Coverage in Your Region?

Why Choose Insight Quality?