Factory Audit Services

What is a Factory Audit?

A factory audit is an important quality assurance tool for importers. We send an auditor to your supplier’s (or potential supplier’s) facilities to ensure compliance with certain predetermined requirements.

While on-site at the factory, the auditor conducts a number of checks and provides a report to aid you in your supply chain decisions. For example, they might be working to determine whether the supplier:

- Has an effective quality management system in place

- Has the capability or capacity to meet your order requirements

- Is operating in line with labor laws or environmental requirements.

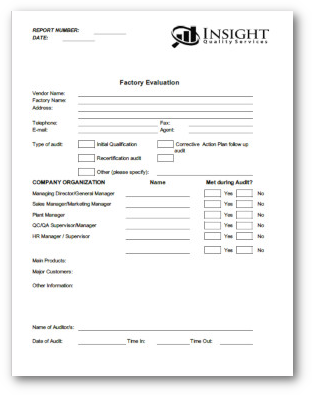

At the end of the audit, you will receive the complete audit report. The report provides detailed information about the auditor’s findings, along with photographs. If there are any issues you should be aware of, you will be notified so that you can handle them appropriately.

Audits are designed to aid you in the sourcing process or to help you manage existing supplier relationships.

Why Should You Conduct a Factory Audit?

Your suppliers will naturally make claims about how they operate and what systems are in place for quality management, environmental management, compliance with labor laws, etc.

Hiring a neutral third-party auditor to go to the factory gives you a more complete picture and allows you to verify any claims a supplier might make or to verify they are up to your standards.

For example, an audit could help you to:

- Decide whether a particular supplier will serve as a suitable long-term partner for your needs.

- Improve efficiency as well as quality in your supply chain by influencing management

- Ensure that your supply chain is free of problematic social or environmental issues

At Insight Quality, we help you to ensure that the suppliers you work with are compliant with all applicable regulations and meet your standards for quality.

5 Types of Factory Audits to Consider

We provide a wide range of quality assurance services to importers. Our audit services cover a number of different areas. We conduct the following types of audits:

The most common type of inspection — also called a Final Random Inspection (FRI). Conducted once your products are 100% complete and at least 80% packaged.

The most common type of inspection — also called a Final Random Inspection (FRI). Conducted once your products are 100% complete and at least 80% packaged.

The most common type of inspection — also called a Final Random Inspection (FRI). Conducted once your products are 100% complete and at least 80% packaged.

The most common type of inspection — also called a Final Random Inspection (FRI). Conducted once your products are 100% complete and at least 80% packaged.

The most common type of inspection — also called a Final Random Inspection (FRI). Conducted once your products are 100% complete and at least 80% packaged.

Download One of Our Sample Inspection Reports

Global Coverage, People-First Approach

- China

- India

- Vietnam

- Bangladesh

- Pakistan

…and more

Need Coverage in Your Region?

Why Choose Insight Quality?