Is the Quality of Products Made in China Really That Bad?

Table of Contents

There is a common perception in the West that China only makes low-quality goods. In many people’s minds, a “Made in China” label may as well say, “This is a cheap, poorly-made product that will break within a few weeks.”

Look at this meme — a great example of this commonly-held attitude. A small yellow car (representing Chinese goods) crashes into an orange bicycle (symbolizing German goods). The “Chinese” car crumples against the rear tire of the “German” bike. What’s funny, though, is that the car appears to be a Chevy!

We have all heard people talk negatively about Chinese goods at one time or another. However, we should stop for a minute to ask an important question — is this perspective warranted? Are goods from China really only worthy of the trash bin after minimal use? And how do you manage product quality if you plan to manufacture there?

Chinese Manufacturing is Not Good or Bad — It’s Both!

Sure, there are poor-quality goods made in China and many other countries. However, memes like the car and bicycle don’t reflect the level of nuance needed to understand the situation.

As a third-party product inspection company, we’ve checked countless goods at factories in China and worldwide. After many inspections, we’ve seen that there are three types of Chinese factories:

- The ones that produce low-quality goods

- The ones that make high-quality goods

- The ones that produce whatever quality of goods you need — depending on how much you pay them!

While plenty of cheap consumer products come out of the country, there are also many Chinese brands that have made a name for themselves in recent years and are well-regarded. Consumer electronics companies such as Lenovo, DJI, and Xiaomi tend to be well-reviewed and have significant global market share.

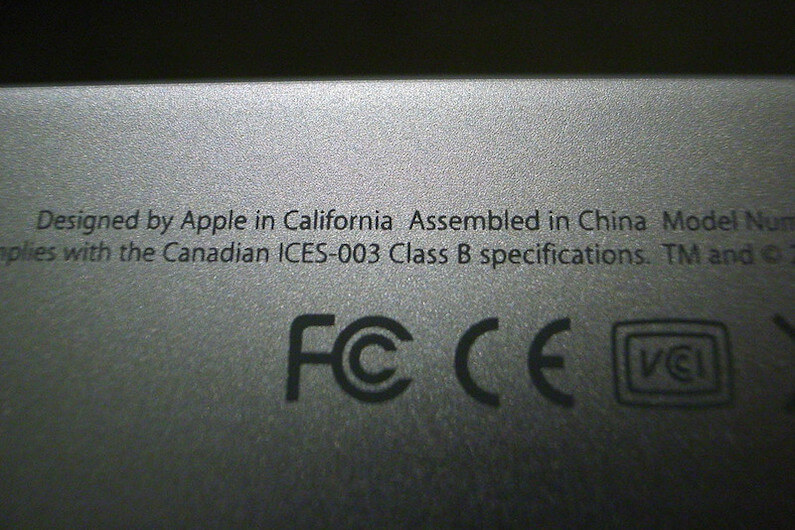

Well-known Western brands like Apple, Coach, and Armani make products in China that people regard as high quality and command high prices. They know that if they provide precise specifications, work collaboratively with suppliers, monitor their manufacturing closely, and get involved in quality control, they will be successful in making high-quality goods.

If you design a new smartphone, chest of drawers, or handbag and want to have it made in China, you can make low-quality goods or high-quality goods. The choice is up to you, but success depends on your skills in product design, supplier development, and quality control.

China is no longer the low-cost, low-skilled manufacturing country it once was. Those days are long gone, and it has emerged as a manufacturing powerhouse and moved steadily up the value chain.

China is Not “Cheap” — It Has Other Advantages

When China opened up to the world over 40 years ago, it was one of the world’s poorest countries. Western nations were able to take advantage of its massive population and workforce to help them produce many cheap consumer goods.

Today, China is an upper-middle-income country, and there are other places with cheaper labor costs — India, Vietnam, and Bangladesh, for example. While these countries have been growing their manufacturing sectors, especially for labor-intensive goods, China still has an immense pull that consistently draws in foreign buyers.

Here are three key reasons why brands decide to make their products in China:

- Efficiency: China has developed a robust manufacturing infrastructure, efficient logistics, and a skilled workforce. This streamlines production, reduces costs, and enables high-value product manufacturing.

- Scale: China’s vast population and labor force enable unmatched manufacturing scale and capacity. This is particularly vital for competitive industries like electronics, textiles, and consumer goods.

- Integration: China has developed well-integrated supply chain ecosystems to optimize raw material sourcing and assembly. This helps reduce lead times and meet market demand promptly.

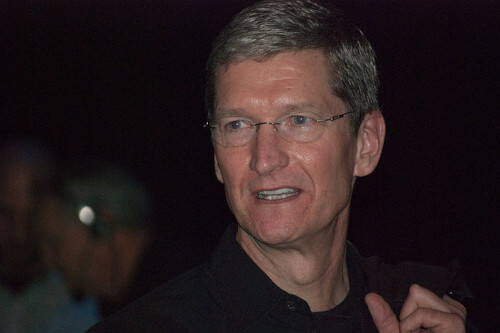

As Tim Cook, the CEO of Apple, said:

As Tim Cook, the CEO of Apple, said:

“There’s a confusion about China. The popular conception is that companies come to China because of low labor cost. I’m not sure what part of China they go to, but the truth is China stopped being the low-labor-cost country many years ago. And that is not the reason to come to China from a supply point of view. The reason is because of the skill, and the quantity of skill in one location and the type of skill it is.”

As Tim Cook indicates in the quote above, China is no longer a low-cost, low-skill country. It has undergone a modernization process and seen an explosion in its manufacturing sector. Let’s talk about that evolution.

Chinese Manufacturing Has Evolved Over Time: This is How

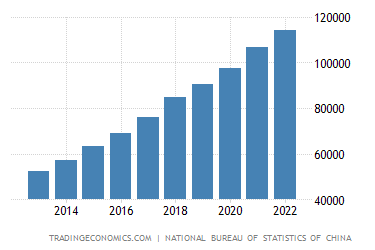

Over the last 40 years, China has gone from an agricultural economy to the world’s leading manufacturer. In 2022, China produced $4.98 trillion worth of goods, accounting for about 30% of all global manufacturing output.

During the last few decades, its manufacturing sector has matured significantly. Factories have improved their processes, quality control, and worker training. Wages and labor costs have risen along with the level of skill and technology in factories.

For example, when labor was cheaper, a plastics factory could quickly push out high volumes of plastic parts with many defects from their injection molding machines. Then they would have workers manually trim and rework them as needed.

Source: tradingeconomics.com

With rising labor costs, that factory had to adapt by operating more efficiently and producing better quality from the beginning. The factory owners and managers also might have realized at some point that they could reorganize the layout of their factory to ensure more lean and efficient operations.

They also would have become more aware of the quality standards and typical requirements of companies in the countries they export to. We’ve seen many factories in China follow this trajectory.

The reality is that, as an importer, if you want to produce very high-quality products in China as luxury brands do, nothing is standing in your way. Some companies make low-value products in China intentionally. However, some do so accidentally, as there are pitfalls to avoid.

Why Do Low-Quality Products Still Come Out of China?

First, you should understand that, like it or not, there is a demand for low-quality products in Western countries. Many global brands realize they can get more sales of their products by selling them at a lower price. To do this, they very consciously choose to sacrifice quality.

As a buyer going to China, you will find factories that can produce your products to various quality standards. It comes down to the demands the brands place on them and how willing they are to spend money on better materials and quality control.

If you come to the factory and say, “I want you to make the highest-quality products for me, and I want you to produce them at rock-bottom, below-market costs,” you are starting things off on the wrong foot.

It would be better to recognize that while you can make products in China at a lower cost than in the West and still get good quality, trying to push your costs down too far is counterproductive. You get what you pay for. Therefore, having reasonable expectations and not focusing on price as the sole factor guiding all your sourcing decisions is infinitely better.

Another thing to consider is that you must design your products well and manage the relationship effectively when dealing with Chinese factories. Otherwise, you risk painful, unexpected quality issues or quality fade that can lead to high defect rates or product recalls. Let’s talk about how to manufacture your product competently.

How to Manage China Factory Relationships and Avoid Quality Issues

If you are thinking of manufacturing your product in China, there are many factories that can and will make things exactly the way you want them. It is crucial, though, that you do three key things:

- Audit: Thoroughly assess any manufacturer you work with by conducting on-site audits at the factory before the first order and periodically after that.

- Specify: Set expectations by consistently providing clear product specifications and ensuring that your supplier agrees to them.

- Control: Develop your own quality control plan, and implement measures such as inspections and testing to regularly verify the quality of work.

We have a saying in our industry that “quality begins with the buy.” As a third-party inspection company, clients sometimes come to us thinking that product inspections are the key to quality, but you can’t inspect quality into a product.

Quality begins with design, and many quality issues you come across in China are actually design issues. If you’ve developed a product with materials, components, or assembly that won’t meet customer needs, it doesn’t matter if the factory produces them precisely the way you asked — the product will be low quality.

Another problem that many companies run into is quality fade. In essence, the factory begins secretly making material substitutions due to the following:

- Pressure to meet your price targets

- A lack of precise specifications, or

- Your complacency with quality standards

As such, the three keys we outlined above are essential if you want to ensure product quality.

Remember That it Falls on the Brand to Ensure Product Quality

Each brand is responsible for deciding how important product quality is to them. Producing high-quality goods in China requires working with suitable suppliers on the basis of mutual respect.

There is a range of suppliers in China with varying capabilities. To get good quality, you should design your products well, provide clear specifications, and plan and implement your own quality control measures. That way, you can get the exact output you are looking for.

Brands that don’t do these things should not be surprised when consumers don’t view their products as high quality. If you’d like to learn more about the distinction between price and quality and how to manage your product’s quality, we recommend downloading the guide below.

Free Guide

Stop Making the same silly quality mistake!

- Learn the secrets to “high” quality products – that save you money!

- Never be confused again by complicated quality data

- See the steps to increase customers’ confidence in your brand

Please Note: This article was originally published on August 19, 2019 and has since been updated.

Download

AQL Inspections 101: How They are Conducted

Authors