During Production Inspections (DUPRO)

Download a Sample ReportWhat is a During Production Inspection?

A During Production Inspection (DUPRO) identifies product issues early in the manufacturing cycle. This inspection is conducted on-site when at least 20% of production has been completed. It generally covers items such as:

- Packaging & Labeling

- Visual Inspection

- Physical Requirements & Dimensions

- Functional Testing

- Special Tests Specific to Your Product

- Barcode Verification

- Drop Testing

- Other Checks, as Necessary

At Insight Quality Services, we use internationally-recognized AQL sampling procedures (ISO 2859-1). This statistically valid method ensures the most accurate results. For any issues we discover, we will provide recommendations on the most appropriate corrective actions.

Why Should You Conduct a DUPRO Inspection?

DUPRO Inspections can serve as an important part of a well-rounded quality assurance program. These inspections are most useful for customers who:

- Are producing large quantities in continuous production

- Are using a vendor for the first time

- Cannot afford delays

- Need detailed reports on production, including statuses, processes, schedules, capacity, and materials

- Need to ensure a vendor is still following their requirements

One of the key benefits of DUPRO Inspections is that they enable you to take corrective action early. You’ll be able to deal with issues while your goods are still in production.

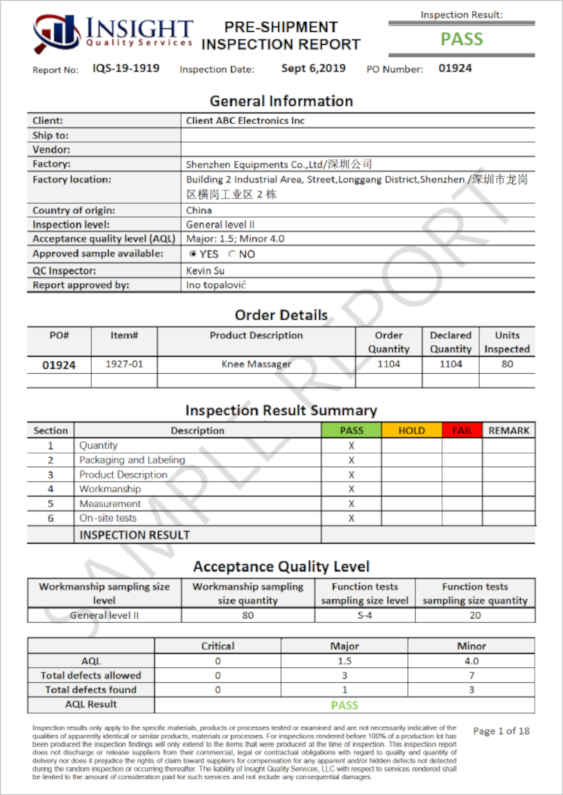

Download One of Our Sample Inspection Reports

Global Coverage, People-First Approach

- China

- India

- Vietnam

- Bangladesh

- Pakistan

…and more

Need Coverage in Your Region?

Why Choose Insight Quality?