How To Approach Functional Testing On Your QC Checklist

Table of Contents

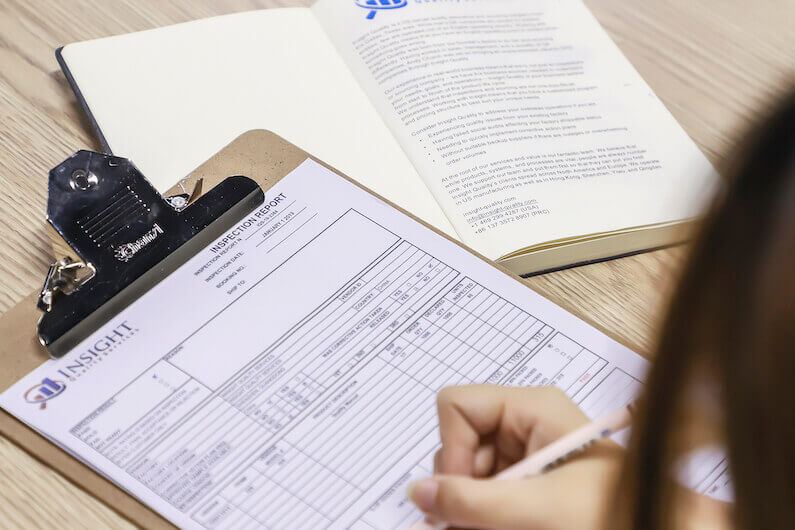

We go to many factories to conduct inspections on behalf of our clients, and every time, the inspector takes an inspection checklist. It lists all the tests and checks they must perform on the product.

Some buyers think they can rely on the QC company to develop their checklist — but this is a mistake. As the brand owner, you understand your products better than anyone. So you’ll get the best results by working together to develop it.

Every inspection checklist includes various sections like packaging and labeling, visual inspection, and the one we will discuss today — functional testing.

Functional testing helps ensure your product works as intended. It also enables you to minimize returns and avoid negative product reviews. Let’s discuss why you need to do functional testing, review some examples, and explain how to improve your checklist.

What is Functional Testing, and Why is it Needed?

Functional testing means testing a product’s typical use or function. This can involve physically using or manipulating it to verify that it conforms to your performance and material requirements.

For example, this might mean turning on an electronic device and pressing buttons to verify that they work. Or, if your product has attachable accessories, it could mean attaching them and then seeing if they stay attached.

Functional testing is important because it gives you a preview of the experience your consumer will have when they use the product. If their experience doesn’t match their expectations, they’ll be more likely to give you a poor review or to return the product. So functional testing is an important part of the inspection checklist. (See: Quality Inspection Checklists: How to Create Them)

What are some examples of functional testing?

Here are 6 Examples of Functional Testing

Let’s take a look at some different products and the functional tests that might be appropriate for them:

- Facial Steamer: Add water to the device and turn it on to verify that steam comes out in the expected manner.

- Cushion: Press down on the cushion to verify firmness. Pull the zipper to ensure that it moves smoothly.

- Travel Tumbler: Pour boiling water into the tumbler and let it sit to ensure coating adherence.

- Headphones: Plug the headphones into a mobile device. Press the Play and Volume buttons to verify that the phone responds.

- Cordless Electric Mop: Turn the mop on and off to check responsiveness. Test the spraying and waxing functions.

- No-Tie Shoelaces: Push the ends of the shoelaces through the eyelets on a shoe. Verify that they fit snugly and stay in place.

What do these tests all have in common? They simulate the actual use of a product by the consumer. So how do you determine which functional tests should go on your checklist?

How to Choose the Right Functional Tests for Your Checklist

When putting together your inspection checklist, think about how the product will be used and what type of experience the consumer is expecting to have.

Imagine yourself in the consumer’s shoes and pull your product out of the box. What do you do with it? How are you going to use it on a regular basis? Think about similar products that you’ve used before — products that perhaps you weren’t thrilled with. What problems did you have?

With these questions in mind, you can come up with ideas for functional testing. Remember that your checklist is a living document that can be modified over time as issues arise and as you learn more about the consumer experience.

Let Us Help You Ensure Product Quality

At Insight Quality, we offer product inspection services and can go to the factory on your behalf. We’ll work with you to ensure your checklist is tailored to your needs, so contact us if you have any questions or would like a quote for product inspection.

If you’d like to learn more about how to prepare for your product inspection, we recommend downloading the guide below.

Free Guide

How to Prepare for an Inspection

Are you thinking of hiring a third-party inspection company? If so, you need to be properly prepared. No one knows your product better than you do. So, make sure you give your service provider the information they need to ensure that your inspections are a success. Download this free guide to successfully preparing for your product inspections.

Note: This article was originally posted in November of 2020 and updated in February of 2024

Download

AQL Inspections 101: How They are Conducted

Authors