Can You Inspect Multiple SKUs In a Single Lot to Cut Costs?

Table of Contents

If you are working with a third-party inspection company (like Insight), you are undoubtedly paying by the “man-day.”

That means that as you place larger orders, your costs will go up since it might take more man-days to complete an inspection.

As an importer concerned about product quality, you know that you need to avoid substandard materials, poor finishing, incorrect sizing, and other quality issues that might arise. But it’s natural to want to minimize your inspection costs in any way you can.

So how do you ensure that you’re utilizing your quality control budget efficiently?

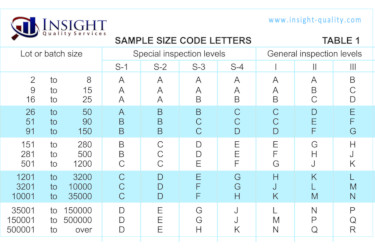

One common way that we help our customers to minimize their inspection costs is through the use of combined sampling. If you are familiar with AQL sampling, you know that the number of products inspected is based on the size of the overall lot. See our overview of AQL Sampling if you need a refresher.

It’s important to note that you can sometimes combine multiple products with different SKUs into a single lot, rather than keeping them in separate lots.

Let’s talk about how combined sampling works and how to determine whether or not it’s appropriate for your situation.

How Does Combined Sampling Work?

To understand how combined sampling works, let’s take a look at an example.

- 500 bottles – 16-ounce, red

- 400 bottles – 16-ounce, blue

- 300 bottles – 20-ounce, red

- 200 bottles – 20-ounce, blue

There are two ways you could handle this, the first being to treat each product as a separate lot, and the second being to combine them into one lot.

Option 1 – Treat each SKU as a separate lot

Based on standard AQL sampling procedures, if you were to inspect each type of bottle in a separate lot, the inspector would need to check:

- 50 bottles – 16-ounce, red

- 50 bottles – 16-ounce, blue

- 50 bottles – 20-ounce, red

- 32 bottles – 20-ounce, blue

In total, they would check 182 bottles. What’s the alternative?

Option 2 – Combine all four SKUs into one lot

When you combine all 1,400 bottles into a single lot, the AQL chart will tell you to inspect 125 bottles in total — that’s less than the 182 bottles from option 1. But how much of each SKU should you inspect? To determine this, we use the following formula:

Item Quantity/Lot Quantity * Sample Size (i.e. 500/1400 * 125)

Using this formula we determine that the inspector will need to check:

- 45 bottles – 16-ounce, red

- 36 bottles – 16-ounce, blue

- 27 bottles – 20-ounce, red

- 18 bottles – 20-ounce, blue

Inspecting 125 bottles will take less time than inspecting 182, and this type of sampling can sometimes reduce the number of man-days required to complete an inspection.

It’s important to keep in mind, though, that combined sampling is not suitable for all situations.

Combined Sampling Can Sometimes Be a Bad Idea

In our hypothetical example, we used plastic water bottles, and this worked out well because the items were all very similar to each other.

For example, if you ordered 1,000 shirts and 700 pairs of pants you would need to inspect them separately, as they are made using different production processes. Or, if you received ceramic mugs from two different factories and were inspecting them in a warehouse, you wouldn’t combine them because they weren’t made in the same location.

The key thing to keep in mind is that combined inspections should only be conducted on products that are of the same type, serve the same function, are produced using the same basic process with the same equipment, and are made at the same factory.

The more dissimilar the products are, the riskier it is to combine them into a single sample.

So, use combined sampling wisely!

For more information about AQL sampling, we recommend you read the following white paper.

As a consumer goods importer, the quality of your products is key to your success. Good quality products will earn you favorable reviews and repeat purchases. Thus, product inspections are important. AQL determines the sample size for your inspections and understanding it is important. Having a good grasp of this method allows you to work with your third-party inspectors more effectively. This white paper will teach you all the basics of the AQL method.

Download

AQL Inspections 101: How They are Conducted

Authors