Pre-Production Inspection (PPI)

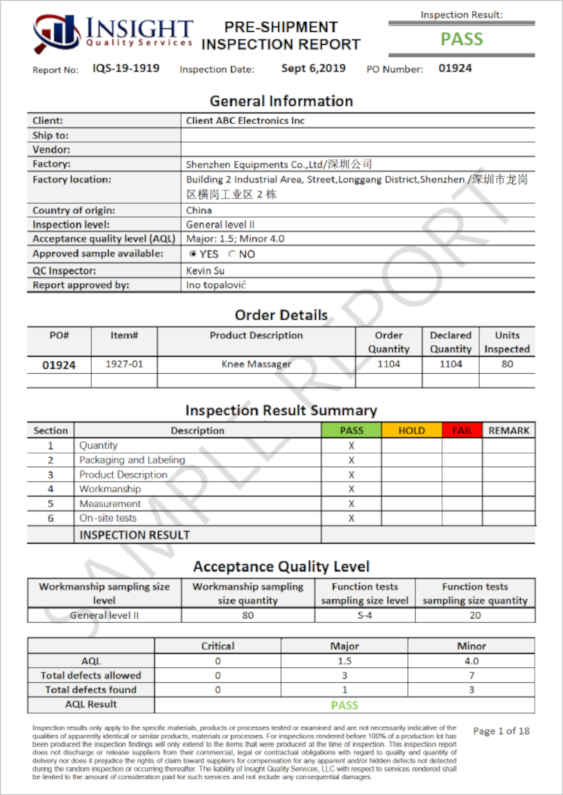

Download a Sample ReportWhat is a Pre-Production Inspection?

A Pre-Production Inspection (PPI) is generally conducted once raw materials are received and the factory is ready to begin production. A PPI can cover a number of different areas. Some common agendas are:

- Verifying that raw materials match the quality specified in the contract

- Checking a prototype product or golden sample

- Ensuring the factory is ready for mass production

Your inspector will go to the factory and check raw materials, prototypes, and/or semi-finished products. They will take photos and issue a report for you to review.

Why Should You Conduct a Pre-Production Inspection?

A Pre-Production Inspection can help you, the importer, to verify whether or not raw material quality is in conformity with the contract. It will also help you verify whether production will proceed on schedule. You should consider a PPI if:

- You are working with a new supplier

- You have a large contract and critical delivery dates

- You are concerned that your supplier may be cutting corners by substituting in cheaper materials

A PPI can also help you verify whether the supplier is on track to follow your agreed-upon production schedule and follow critical manufacturing requirements. It helps eliminate communication gaps between the importer and exporter.

Download One of Our Sample Inspection Reports

Global Coverage, People-First Approach

- China

- India

- Vietnam

- Bangladesh

- Pakistan

…and more

Need Coverage in Your Region?

Why Choose Insight Quality?